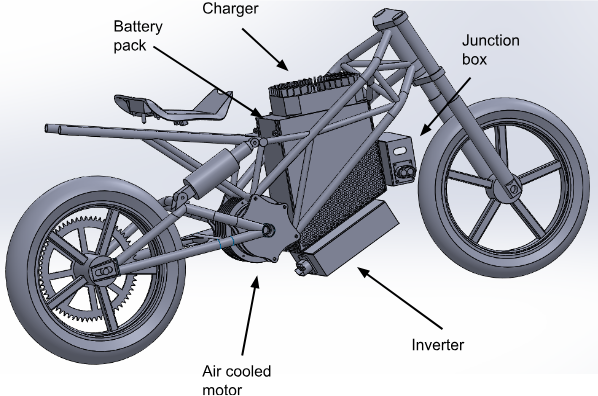

Project Objective

The objective of this project is to design and build an electric motorcycle from scratch, gain some knowledge and share it with likeminded people (if there are any?). An important sub-objective is to design and build the drive train, including a 3-phase PMSM electric motor, an inverter for the motor and a battery pack to power the whole thing.

Motor

The heart of the project is the 3-phase brushless permanent magnet synchronous motor (PMSM). It’s a 8 pole, 48 slot design (8p48s). The rotor has a width of 108mm, a diameter of 100 mm and is fitted with neodymium magnets. The housing and the fins are made of aluminum, while the stator and rotor are made of 29 gauge M19 electrical steel.

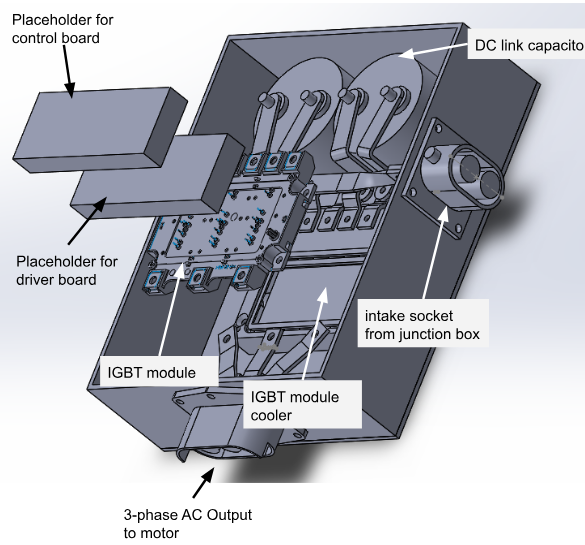

Inverter

If the motor is the heart of the project, the inverter is the brain. The purpose of the inverter is basically to make the motor spin. It does so by converting the DC voltage of the battery to a sinusoidal AC current, in the stator windings, of a specific amplitude, frequency and phase in relation to the rotor position. The alternating current in the stator windings create a rotating magnetic field, a magnetic field the rotor with its permanent magnets align with – resulting in a rotating rotor.

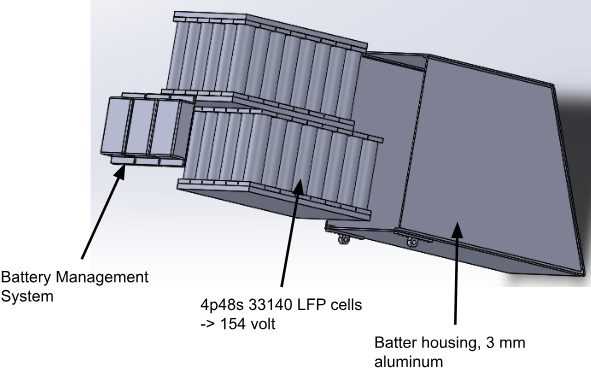

Battery

The battery pack is made up of 96 33140 LFP (Lithium Ferro Phosphate) cells. This battery chemistry is sometimes also called LiFePo4. The 33140 is the form factor, with a diameter of 33 mm and height / length of 140 mm. Each cell has a nominal voltage of 3.2 volt and the pack configuration is 48s4p, which means 48 cells in series and 4 cells parallel, giving the total pack a nominal voltage of 154 volt. The max discharge current per cell is 75 A and with 4 cells in parallel, the maximum discharge current is 300 A, which should be enough during acceleration.

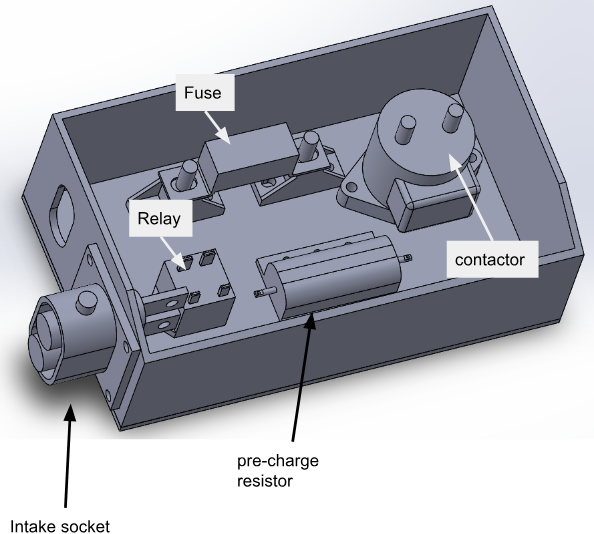

Junction Box

The junction box sits between the battery and the inverter and contains the main contactor, main fuse and the pre-charge resistor.

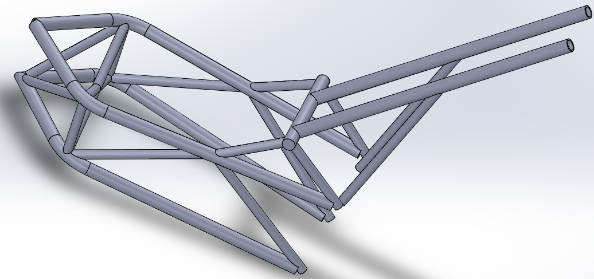

Frame

The motorcycle itself is built with steel tubes that are welded together. Although steel pipes aren’t the most exotic choice of material you can build very capable frames from them, proven by e.g. Ducati who only recently switched to aluminum. The frame types built from steel pipes are called trellis or lattice frames. The main advantage is the ease of construction and cost effectiveness for on-offs or smaller series.